Ever stared at a piece of metal and wondered how to cut it cleanly and safely? You’ve probably seen those powerful angle grinders, but the discs that attach to them can be confusing. Picking the wrong disc can mean slow cuts, sparks flying everywhere, or even a dangerous accident.

Choosing the right angle grinder disc for cutting metal isn’t always easy. There are so many different types, and they all look a bit alike. You want a disc that cuts fast, lasts a long time, and keeps you safe. But how do you know which one is best for your project? It’s a common problem for DIYers and even seasoned professionals.

By reading on, you’ll learn exactly what makes one disc better than another for cutting metal. We’ll break down the different types of discs, explain what to look for, and give you tips to make your metal cutting jobs much smoother and safer. Get ready to master your angle grinder!

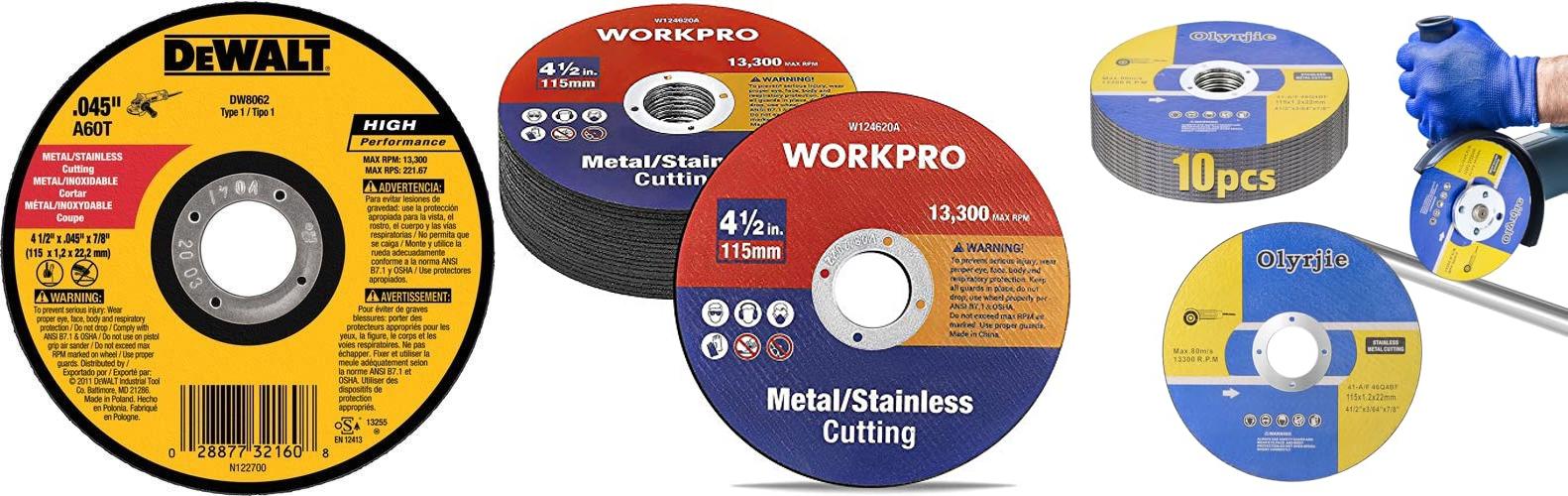

Our Top 5 Angle Grinder Disc For Cutting Metal Recommendations at a Glance

Top 5 Angle Grinder Disc For Cutting Metal Detailed Reviews

1. DEWALT 4-1/2 Inch Cut-Off Wheel

Rating: 8.7/10

The DEWALT 4-1/2 Inch Cut-Off Wheel, Angle Grinder Cutting Disc, General Purpose, 4-Pack (DW8062B5) is a powerful tool for any DIYer or professional. It’s designed to make your cutting jobs easier and faster. This pack comes with four wheels, so you have plenty to get the job done.

What We Like:

- More Cuts. Fewer Wheels.™: These wheels last much longer. They use special grains that are super sharp and tough. This means you can make more cuts before needing to change a wheel.

- Extremely Versatile: You can cut many different types of metal with these wheels. This includes regular steel, stainless steel, and special nickel alloys.

- Aggressive Cutting Action: The wheels are thin and packed with grains. This helps them cut through metal very quickly.

- Durable By Design: The wheels are built strong. They have two layers of fiberglass to prevent them from breaking. This makes them safer to use.

- Cuts Many Materials: You can use these wheels to cut steel, angle iron, pipe, tubing, and rebar.

What Could Be Improved:

- Dust Generation: While they cut well, these wheels can create a good amount of dust. You should always wear a dust mask when using them.

- Wheel Wear: Even though they last longer than some others, they will still wear down with heavy use.

Overall, these DEWALT cut-off wheels are a reliable choice for a variety of metal cutting tasks. They offer good value and performance for their price.

2. WORKPRO 20-Pack Cut-Off Wheels

Rating: 8.9/10

Tackle your metal cutting jobs with ease using the WORKPRO 20-Pack Cut-Off Wheels. This set includes 20 thin cutting discs, each designed for 4-1/2 inch angle grinders. They are made to cut through metal and stainless steel quickly and cleanly. You get a lot of wheels for a good price, making it a smart choice for DIYers and professionals alike.

What We Like:

- Great value with a 20-pack offer.

- Cuts metal and stainless steel very fast.

- The thin design means less waste and cleaner cuts.

- Built with strong materials like corundum and white alundum for durability.

- Reinforced with fiberglass mesh for extra safety and a longer lifespan.

- Works well with most 4-1/2 inch angle grinders.

- Can handle high speeds up to 13,000 RPM.

- Good for cutting steel, stainless steel, pipes, iron, copper, and other metals.

What Could Be Improved:

- While durable, heavy-duty, continuous use might wear them down faster than thicker wheels.

- The “thin” design, while efficient, might require more caution to prevent bending or breaking on very thick or stubborn materials.

Overall, these WORKPRO cut-off wheels are a reliable and cost-effective option for many metalworking projects. They offer good performance and safety for their price point.

3. 10 Pack 4 1/2 in Cut Off Wheel Cutting Wheels for Angle Grinders

Rating: 9.1/10

Tackle your metal cutting tasks with this 10-pack of 4 1/2-inch ultra-thin cut-off wheels. These cutting discs are designed for your angle grinder and are perfect for cutting various metal materials.

What We Like:

- These wheels are super thin, only 1/64-inch. This makes them cut metal really fast and accurately.

- They work with any 4 1/2-inch angle grinder you might have.

- You can use them to cut steel, pipes, iron, and copper. They’re great for jobs in factories, car repair, building, and fixing things.

- The design includes air holes. These help blow away dust and keep the wheel cool so it doesn’t get damaged.

What Could Be Improved:

- These wheels are not meant for cutting aluminum alloys.

- Always remember to wear safety glasses and gloves when you use them. You also need to make sure your angle grinder is steady and the disc is on tight to avoid accidents.

These cutting wheels offer efficient and precise metal cutting for a variety of projects. Just be sure to follow safety guidelines for the best results.

4. DeWalt DW8062 4-1/2″x.045″x7/8″ Metal Angle Grinder Thin Cutoff Wheel

Rating: 8.9/10

The DeWalt DW8062 4-1/2″x.045″x7/8″ Metal Angle Grinder Thin Cutoff Wheel, 10 Pack is a handy set of wheels for your angle grinder. These thin wheels help you cut metal quickly and cleanly. You get ten wheels in this pack, which is great for having extras on hand.

What We Like:

- These wheels are very thin, only .045 inches. This makes cutting fast and leaves fewer burrs.

- They are easy to use with your angle grinder.

- The wheels are made to last a long time.

- The special aluminum oxide grain helps them cut aggressively.

- Two layers of fiberglass make them strong and safe.

- You get a set of 10 wheels for fast, burr-free cutting.

What Could Be Improved:

- While durable, some users might wish for even longer life on very tough jobs.

- The wheels are manufactured in China, which might be a consideration for some buyers.

Overall, this 10-pack of DeWalt cutoff wheels offers great performance for metal cutting tasks. They are a reliable choice for many projects.

5. SALI 50 Pack Cut Off Wheel 4 1/2 Inch Cutting Wheels 4-1/2″ x 3/64″ x 7/8″ for Metal & Stainless Steel

Rating: 8.9/10

Tackle your metal cutting projects with confidence using the SALI 50 Pack Cut Off Wheel. These 4 1/2 inch cutting wheels are designed for metal and stainless steel. They work with your angle grinder to make fast, clean cuts. This big pack gives you plenty of wheels for many jobs.

What We Like:

- You get 50 cutting wheels in this pack, so you have plenty for lots of projects.

- The thin 0.045-inch design helps you cut metal quickly and without rough edges.

- They are made with a special aluminum oxide grain that cuts aggressively and lasts a long time.

- The wheels are reinforced with fiberglass mesh, making them safer and stronger.

- They fit all 4 1/2 inch angle grinders with a 7/8 inch arbor and can spin up to 13,300 RPM.

What Could Be Improved:

- While the aluminum oxide grain is good for cutting, it might wear down faster on very tough materials compared to other types of grains.

These SALI cutting wheels are a solid choice for anyone who frequently works with metal. They offer good performance and a great value with the large pack size.

Choosing the Right Angle Grinder Disc for Cutting Metal

Cutting metal can be tough work. You need the right tool for the job. An angle grinder is powerful, but the disc you use makes all the difference. This guide helps you pick the best metal cutting disc for your needs.

Key Features to Look For

When you shop for metal cutting discs, some things stand out.

1. Grit Size

- Coarse Grit: These discs cut faster. They are good for thicker metal or rougher cuts.

- Fine Grit: These discs make smoother cuts. They are better for thinner metal or when you want a cleaner finish.

2. Abrasive Material

- Aluminum Oxide: This is common. It works well for general metal cutting.

- Zirconia Alumina: This is tougher. It lasts longer and cuts harder metals.

- Silicon Carbide: This is very hard. It’s good for cutting non-ferrous metals like aluminum and brass.

3. Disc Thickness

- Thin Discs (e.g., 1/16 inch or 1.6mm): These cut metal quickly and with less effort. They are great for precise cuts. However, they wear out faster.

- Thicker Discs (e.g., 1/4 inch or 6.4mm): These are more durable. They are good for heavy-duty cutting and last longer. They can be slower and create more sparks.

4. Arbor Size

- Make sure the hole in the disc fits your angle grinder’s spindle. The most common size is 7/8 inch (22.2mm). Always check your grinder’s manual.

Important Materials

Metal cutting discs use different abrasive grains. These grains are mixed with a binder and then pressed into a disc shape. The quality of these materials affects how well the disc cuts and how long it lasts.

- Abrasive Grains: These do the actual cutting. Aluminum oxide, zirconia alumina, and silicon carbide are popular choices.

- Binder: This holds the abrasive grains together. It needs to be strong but also allow the grains to break away when they get dull.

- Reinforcement: Many discs have fiberglass or mesh layers. This adds strength and prevents the disc from shattering during use.

Factors That Improve or Reduce Quality

Several things make a metal cutting disc better or worse.

- High-Quality Abrasive Grains: Discs with better abrasive materials will cut faster and last longer.

- Strong Binder: A good binder keeps the disc from falling apart too soon.

- Proper Reinforcement: Strong fiberglass backing stops the disc from breaking.

- Manufacturing Process: How the disc is made matters. Good manufacturing leads to a more consistent and safer product.

- Using the Wrong Disc: Trying to cut something with a disc not meant for it will reduce its quality and can be dangerous.

- Overheating: Pushing the grinder too hard can make the disc wear out faster.

User Experience and Use Cases

How you use the disc and what you cut with it are important.

- DIY Projects: For home use, cutting pipes, rebar, or sheet metal, a standard aluminum oxide disc is usually fine.

- Professional Fabrication: If you cut metal all day, you’ll want tougher discs like zirconia alumina. Thin discs are great for quick, clean cuts.

- Metal Types: Always choose a disc designed for the type of metal you are cutting. Cutting stainless steel might need a different disc than cutting mild steel.

- Safety: Always wear safety glasses, gloves, and hearing protection. Ensure the disc is rated for the speed of your angle grinder.

Frequently Asked Questions (FAQ)

Q: What is the most important thing to look for when buying a metal cutting disc?

A: The most important thing is to make sure the disc is specifically made for cutting metal. Also, check that it fits your angle grinder’s size and speed rating.

Q: Can I use a wood cutting disc on metal?

A: No, you should never use a wood cutting disc on metal. It is very dangerous and the disc will break.

Q: How do I know if a disc is safe for my angle grinder?

A: Check the RPM rating on the disc. It should be equal to or higher than the maximum RPM of your angle grinder. Also, ensure the arbor size matches your grinder’s spindle.

Q: Which disc is best for cutting thin metal sheets?

A: Thin discs, like 1/16 inch (1.6mm) thick, are best for thin metal sheets. They cut fast and make clean edges.

Q: What kind of disc should I use for cutting thicker metal like pipes or bars?

A: For thicker metal, you might want a slightly thicker disc or one with a more durable abrasive like zirconia alumina. These cut through tougher material more easily.

Q: How long do metal cutting discs usually last?

A: The lifespan of a disc depends on the material you’re cutting, how hard you push, and the quality of the disc itself. Thicker discs generally last longer than thin ones.

Q: What does “grit size” mean on a cutting disc?

A: Grit size refers to the coarseness of the abrasive material. Larger grit numbers mean finer grit, which makes smoother cuts. Smaller grit numbers mean coarser grit, which cuts faster.

Q: Can I use a disc for cutting metal on stainless steel?

A: Some metal cutting discs work on various metals, but stainless steel is harder. Look for discs specifically rated for stainless steel or harder metals to get the best results and longest life.

Q: What are the risks of using a damaged cutting disc?

A: Using a damaged disc is extremely dangerous. It can shatter and send pieces flying, causing serious injury. Always inspect discs before use.

Q: Where is the best place to buy angle grinder discs for cutting metal?

A: You can find them at hardware stores, home improvement centers, and online retailers that specialize in tools and hardware.

In conclusion, every product has unique features and benefits. We hope this review helps you decide if it meets your needs. An informed choice ensures the best experience.

If you have any questions or feedback, please share them in the comments. Your input helps everyone. Thank you for reading.

Hi, I’m Hector Quintanilla, the creator of helmetslab.com.. As a passionate enthusiast and experienced expert in helmets, I’ve dedicated this platform to sharing my insights, knowledge, and hands-on experiences. Whether you’re seeking the best helmet for safety, comfort, or performance, my goal is to guide you with detailed reviews, tips, and advice. Ride safe, and let’s explore the world of helmets together!