Ever tried to cut through tough metal and felt like you were wrestling a bear? You know that feeling when your tool just isn’t cutting it, and you’re left with jagged edges and a whole lot of frustration? Choosing the right cut-off wheel can be the difference between a clean, quick job and a messy, time-consuming headache.

There are so many types of cut-off wheels out there, made from different stuff and designed for different tasks. It’s easy to get lost in the options and pick the wrong one, which can not only ruin your project but also be dangerous. But what if there was a simple way to understand which wheel is best for your needs?

In this post, we’re going to break down the world of cut-off wheels. We’ll help you understand what makes them work and how to pick the perfect one for your next project, whether you’re cutting metal pipes, tiles, or something else entirely. Get ready to say goodbye to frustration and hello to smooth, precise cuts!

Our Top 5 Cut Off Wheel Recommendations at a Glance

Top 5 Cut Off Wheel Detailed Reviews

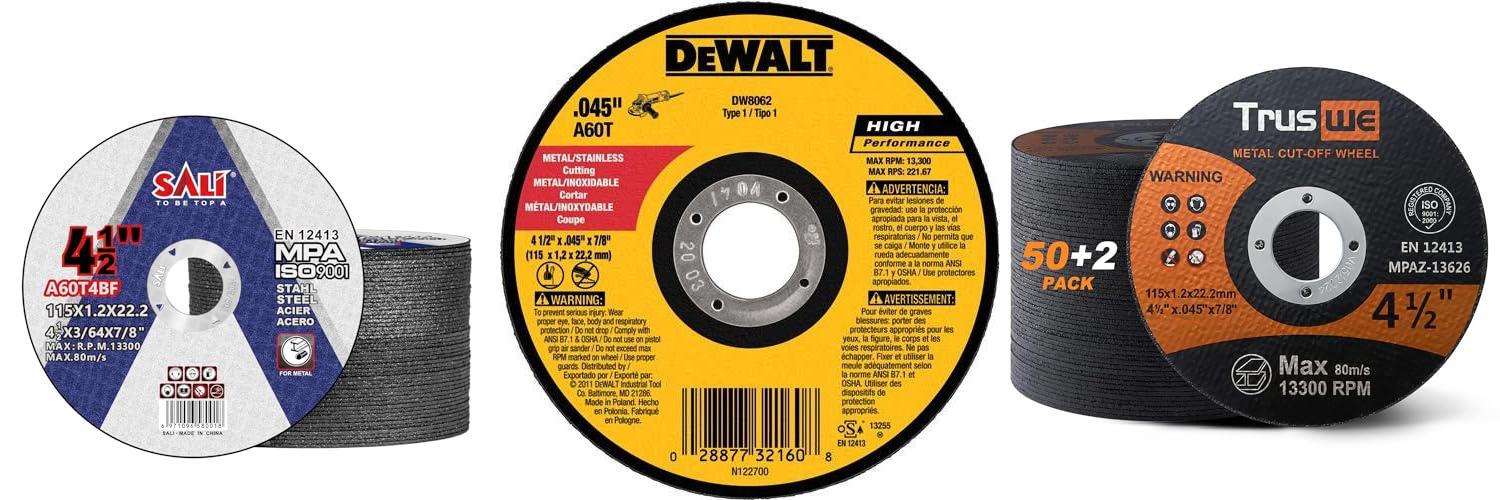

1. SALI 50 Pack Cut Off Wheel 4 1/2 Inch Cutting Wheels 4-1/2″ x 3/64″ x 7/8″ for Metal & Stainless Steel

Rating: 9.0/10

Tackle your metal cutting projects with confidence using the SALI 50 Pack Cut Off Wheel. These 4 1/2 inch cutting wheels are designed for metal and stainless steel. They fit easily onto your 4 1/2 inch angle grinder. You get a generous pack of 50 wheels, so you’ll have plenty for many jobs.

What We Like:

- You get 50 wheels, which is a great value for your money.

- The thin .045-inch design helps you cut quickly and cleanly, with less mess.

- These wheels are made with special aluminum oxide for tough cutting jobs and last a long time.

- They are built with double fiberglass mesh for extra safety and strength.

- They work with most 4 1/2 inch angle grinders.

What Could Be Improved:

- Always remember to wear safety glasses and other protective gear when using these.

These SALI cutting wheels offer a good balance of performance and value. They are a reliable choice for your metalworking needs.

2. DEWALT 4-1/2 Inch Cut-Off Wheel

Rating: 8.8/10

Tackle your metal cutting tasks with the DEWALT 4-1/2 Inch Cut-Off Wheel, Angle Grinder Cutting Disc, General Purpose, 4-Pack (DW8062B5). This pack of four wheels is designed for serious work, making your angle grinder more effective. You’ll spend less time changing discs and more time getting the job done.

What We Like:

- More Cuts. Fewer Wheels.™: These wheels last longer. Temper Point grains are strong and sharp. They make more cuts before needing replacement.

- Extremely Versatile: Cut many types of metal. This includes carbon steel, stainless steel, and nickel-based alloys.

- Aggressive Cutting Action: Make quick cuts. The thin design and lots of grains help you cut fast.

- Durable By Design: Built tough with two layers of fiberglass. This makes the wheels strong and less likely to break.

- Cuts a Variety of Materials: Works well on steel, angle iron, pipe, tubing, and rebar.

What Could Be Improved:

- While the wheels are durable, some users might find they wear down faster on very demanding, continuous jobs compared to specialized discs.

- The “general purpose” nature means they might not be the absolute fastest for every single specific metal type.

For most metal cutting jobs, the DEWALT DW8062B5 offers excellent value and performance. You get a lot of cuts from each wheel, saving you time and money.

3. Truswe Cut Off Wheels 52 Pack

Rating: 8.6/10

Tackle your metal cutting projects with the Truswe Cut Off Wheels 52 Pack. These 4 1/2 inch discs are designed for your angle grinder and are super thin at just 0.045 inches. They’re made for cutting metal and stainless steel, and you get a lot of them for a great price – only $0.45 per pack! This means you can keep working without running out of discs.

What We Like:

- They fit all 4 1/2 inch angle grinders perfectly with a standard 7/8 inch hole.

- The ultra-thin design makes cuts fast and clean, with less waste.

- They are built tough with aluminum oxide grains and a double fiberglass mesh for safety and durability.

- You can use them on many different materials like steel, iron, plastic, and fiberglass.

- You get 52 wheels, which is a fantastic value for your money.

What Could Be Improved:

- While they are safe, always remember to wear all your safety gear when using them, just like with any cutting tool.

These Truswe Cut Off Wheels offer a lot of bang for your buck. They’re a reliable choice for most metal cutting jobs you’ll face.

4. SUPMAMMOTH 55 Pack 4 1/2 Cut Off Wheel Angle Grinder Cutting Disc for Metal & Stainless Steel Cutting Wheel Ultra Thin 0.045” x 7/8 Arbor

Rating: 8.9/10

Tackle your metal cutting projects with confidence using the SUPMAMMOTH 55 Pack 4 1/2 Cut Off Wheel. These ultra-thin discs are designed for your 4 1/2 inch angle grinder and work great on metal and stainless steel.

What We Like:

- Perfect Fit: These 4 1/2 inch cut off wheels fit all 4 1/2 inch angle grinders with a 7/8 inch arbor. They can spin up to 13,300 RPM.

- Built to Last: Made with tough aluminum oxide grains and reinforced with fiberglass mesh, these wheels last longer and cut faster and safer. They are built to EU EN 12413 standards.

- Efficient Cutting: The 0.045 inch thin design makes cutting fast and clean with fewer burrs and less waste. This means less cleanup and more work done.

- Cuts Through Anything: Use these wheels for clean cuts on metal, fiberglass, iron, copper, plastic, steel, stainless steel, and cast iron.

What Could Be Improved:

- Safety First: Always wear safety glasses, ear protection, and gloves when using these discs. Do not go faster than the recommended speed.

These SUPMAMMOTH cut off wheels deliver excellent performance for a variety of metalworking tasks. They are a reliable choice for any DIYer or professional.

5. Benchmark Abrasives Grinder Cut Off Wheels 4 1/2 Inch Aluminum Oxide Thin Type 1 Angle Grinder Cutting Disc for Metal

Rating: 8.5/10

Tackle your metal cutting projects with the Benchmark Abrasives 4 1/2 Inch Grinder Cut Off Wheels. These thin, aluminum oxide wheels are designed for fast, efficient cutting of metal, stainless steel, pipes, and rebar. They are perfect for general metal fabrication and deliver clean, precise results every time.

What We Like:

- Versatile Cutting: These wheels work great on a variety of metals, including stainless steel, aluminum, cast iron, and rebar.

- Flat Design: The Type 1 flat design makes them ideal for both cutting and grinding tasks.

- Efficient Performance: They offer a high cutting rate and smooth, vibration-free cuts, up to 13,000 RPM.

- Wide Compatibility: These 4 1/2 inch wheels fit most 4 1/2 inch and 5 inch angle grinders, as well as other types of saws.

- Durable Construction: Made from high-speed steel and premium materials, they meet high safety standards.

- Great Value: The 50-count pack provides excellent value for frequent users.

What Could Be Improved:

- Thin Design Limitation: While great for speed, the thin design might wear down faster on very heavy-duty, prolonged grinding jobs compared to thicker wheels.

If you need reliable and efficient cutting discs for metalwork, this 50-count pack from Benchmark Abrasives is a solid choice. They offer a great balance of performance and value.

Your Ultimate Guide to Choosing the Right Cut-Off Wheel

Cut-off wheels are like the sharp knives of the workshop. They help you slice through tough materials with ease. Whether you’re a DIY enthusiast or a seasoned pro, picking the right cut-off wheel makes all the difference. Let’s dive into what you need to know.

Key Features to Look For

1. Diameter and Arbor Size

Cut-off wheels come in different sizes. Think about the tool you’ll use. Most angle grinders have standard arbor sizes, usually 7/8 inch. The wheel’s diameter matters too. Bigger wheels can cut deeper, but they need a more powerful grinder.

2. Grit and Abrasive Material

The grit is how rough the wheel is. Finer grit means smoother cuts, but it takes longer. Coarser grit cuts faster but can leave a rougher edge. The abrasive material is what does the cutting. Common ones include aluminum oxide, silicon carbide, and ceramic alumina. Each is good for different jobs.

3. Thickness

Thinner wheels cut faster and create less dust. They are great for precise cuts. Thicker wheels last longer and are better for heavy-duty work where durability is key.

4. Reinforcement

Many cut-off wheels have fiberglass mesh inside. This reinforcement makes them stronger and safer. It helps prevent the wheel from shattering during use. Always look for reinforced wheels.

Important Materials

Cut-off wheels are made of abrasive grains glued together with a binder. The type of abrasive grain and the binder are super important.

- Abrasive Grains:

- Aluminum Oxide: Good for cutting metal like steel. It’s a common and affordable choice.

- Silicon Carbide: Better for harder materials like stone, concrete, and non-ferrous metals.

- Ceramic Alumina: This is a tougher abrasive. It lasts longer and cuts faster, especially on tough metals.

- Binder:

- Resinoid: This is a strong binder that holds the abrasive grains together well. It’s great for high-speed cutting.

- Vitrified: This is like a ceramic binder. It’s good for cooler cuts and is often used for grinding.

Factors That Improve or Reduce Quality

Quality Boosters

- High-quality Abrasive Grains: Better grains mean faster, cleaner cuts and longer wheel life.

- Strong Binder: A good binder keeps the grains in place, preventing premature wear.

- Proper Reinforcement: Fiberglass mesh adds safety and durability.

- Consistent Manufacturing: Wheels made with precision are less likely to break.

Quality Reducers

- Low-quality Abrasives: They wear out quickly and don’t cut well.

- Weak Binder: Can cause the wheel to break apart easily.

- Lack of Reinforcement: Makes the wheel dangerous to use.

- Uneven Thickness: Can lead to wobbling and poor cuts.

User Experience and Use Cases

Using a cut-off wheel is straightforward, but safety is key. Always wear safety glasses, gloves, and hearing protection. Make sure the wheel is securely attached to your grinder.

Common Uses

- Cutting Metal: This is the most common use. You can cut pipes, rebar, sheet metal, and bolts.

- Cutting Tile and Stone: With the right wheel, you can make clean cuts in ceramic tiles, bricks, and concrete.

- Removing Rust and Paint: Some wheels are designed for cleaning surfaces.

- Making Slots: You can cut narrow grooves into materials.

A good cut-off wheel feels balanced on your grinder. It cuts smoothly without excessive vibration. A poor-quality wheel might spark a lot, feel rough, or wear down too fast. Choosing the right wheel for your specific project will make your work easier and safer.

Frequently Asked Questions about Cut-Off Wheels

Q1: What’s the difference between an aluminum oxide wheel and a silicon carbide wheel?

A1: Aluminum oxide is best for general metal cutting, like steel. Silicon carbide is better for harder materials like concrete, stone, and non-ferrous metals.

Q2: How do I know what size cut-off wheel I need?

A2: Check the size of your angle grinder’s arbor. Most are 7/8 inch. The wheel diameter should match what your grinder can handle.

Q3: Is it safe to use a cut-off wheel that looks worn down?

A3: No, it’s not safe. Worn-down wheels can break apart. Always replace them when they get too small or damaged.

Q4: Can I use a cut-off wheel to grind metal?

A4: While some wheels can do a bit of grinding, cut-off wheels are designed for cutting. Using them for grinding can damage the wheel and be unsafe.

Q5: How long should a cut-off wheel last?

A5: The lifespan depends on the material you’re cutting, how hard you press, and the quality of the wheel. High-quality wheels last much longer.

Q6: What does “reinforced” mean on a cut-off wheel?

A6: It means the wheel has fiberglass mesh inside. This makes it stronger and helps prevent it from shattering during use, which is a major safety feature.

Q7: Should I choose a thin or thick cut-off wheel?

A7: Thin wheels cut faster and create less dust, good for precision. Thick wheels last longer and are better for heavy-duty tasks.

Q8: What safety gear do I need when using a cut-off wheel?

A8: You absolutely need safety glasses, gloves, and hearing protection. A dust mask is also a good idea.

Q9: Can I use a cut-off wheel on wood?

A9: No, cut-off wheels are not designed for wood. They can cause kickback and damage. Use a saw blade made for wood instead.

Q10: What is the ideal RPM for a cut-off wheel?

A10: Always use a cut-off wheel that is rated for the maximum RPM of your grinder. The wheel’s packaging will usually state this information.

In conclusion, every product has unique features and benefits. We hope this review helps you decide if it meets your needs. An informed choice ensures the best experience.

If you have any questions or feedback, please share them in the comments. Your input helps everyone. Thank you for reading.

Hi, I’m Hector Quintanilla, the creator of helmetslab.com.. As a passionate enthusiast and experienced expert in helmets, I’ve dedicated this platform to sharing my insights, knowledge, and hands-on experiences. Whether you’re seeking the best helmet for safety, comfort, or performance, my goal is to guide you with detailed reviews, tips, and advice. Ride safe, and let’s explore the world of helmets together!