Ever tried to cut plywood and ended up with rough edges and splintered mess? It’s a common frustration for woodworkers, turning a smooth project into a bumpy ride. Choosing the right blade for your table saw when cutting plywood can feel like navigating a maze. Too many teeth, not enough teeth, different carbide types – it’s enough to make anyone scratch their head.

But what if there was a way to cut plywood like a pro, with clean, crisp lines every single time? This post is here to help you conquer that challenge. We’ll break down exactly what makes a plywood blade special and guide you through the options so you can stop guessing and start cutting with confidence.

By the end of this guide, you’ll know which blade will give you those perfect plywood cuts, saving you time and effort on your projects. Get ready to transform your plywood cutting experience!

Our Top 5 Plywood Blade For Table Saw Recommendations at a Glance

Top 5 Plywood Blade For Table Saw Detailed Reviews

1. 10-Inch Miter/Table Saw Blades

Rating: 9.0/10

Get ready for super smooth cuts with the 10-Inch Miter/Table Saw Blades. This 80-tooth blade is designed for a fine finish, perfect for all sorts of wood projects. Its tough construction means it can handle lots of work.

What We Like:

- The 80-tooth count and ATB design give you really clean, smooth cuts.

- It’s made from strong alloy steel with tough tungsten carbide teeth that stay sharp.

- The shiny chrome-plated surface helps it last a long time.

- It cuts through many kinds of wood and even some plastics and FRP easily.

- It works with both corded and cordless saws, including miter and table saws.

- The thin kerf means less waste and faster cutting.

What Could Be Improved:

- While great for fine finishes, it might not be the best choice for rougher, faster cuts where chip removal is the main goal.

- The 5/8 inch arbor is standard but always double-check your saw’s compatibility.

This blade is a fantastic option for anyone who wants precise, clean cuts in their woodworking. It delivers great results across a wide range of materials.

2. WEN BL1080 10-Inch 80-Tooth Carbide-Tipped Ultra-Fine Finish Professional Woodworking Saw Blade for Miter Saws and Table Saws

Rating: 9.2/10

The WEN BL1080 10-Inch 80-Tooth Carbide-Tipped Ultra-Fine Finish Professional Woodworking Saw Blade is a fantastic tool for anyone who loves working with wood. It’s designed to give you super clean and smooth cuts every time, making your projects look professional. This blade works great on both hard and soft woods, so you can use it for lots of different woodworking tasks.

What We Like:

- It has a 10-inch diameter and fits most 10-inch miter saws, jobsite saws, and table saws.

- The 80 carbide-tipped teeth create an ultra-fine finish, meaning your wood edges will be very smooth and clean.

- Its ultra-thin 1/10-inch kerf cuts through wood efficiently, saving you material.

- It can handle speeds up to 6000 RPM, making it powerful enough for tough jobs.

- This blade is perfect for making precise cuts in all types of hardwoods and softwoods.

What Could Be Improved:

- While it’s great for fine finishes, it might not be the best choice if you need to make rough, fast cuts where a super smooth edge isn’t important.

- The ultra-fine finish might require a slightly slower feed rate through the wood to get the best results.

Overall, the WEN BL1080 is a top-notch blade for woodworking enthusiasts. It helps you achieve professional-looking results with its clean and precise cuts.

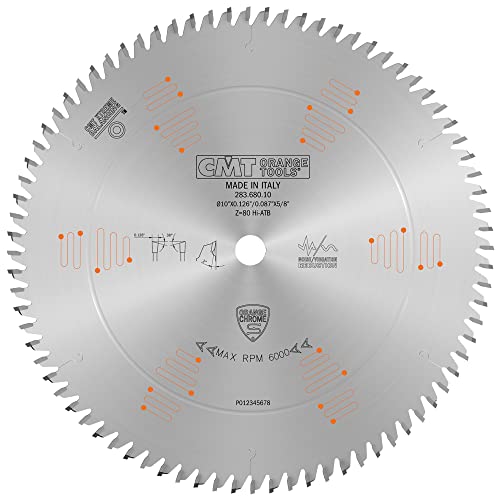

3. CMT ORANGE TOOLS 283.680.10 Orange Chrome Ultimate Plywood & Melamine Blade 10″ x T80 HiATB

Rating: 8.7/10

The CMT ORANGE TOOLS 283.680.10 Orange Chrome Ultimate Plywood & Melamine Blade is a fantastic tool for anyone working with plywood and melamine. This 10-inch blade is designed for precision and leaves a super smooth finish on your projects. Its special HiATB tooth design helps cut through materials cleanly, making your work look professional. You can use it on both your miter saw and table saw, which makes it very versatile.

What We Like:

- It creates a very clean and smooth cut, perfect for melamine and plywood.

- The 80 HiATB teeth help prevent chipping and splintering.

- It works well on both chop miter saws and table saws.

- The blade is built tough for lasting performance.

- It’s made for fine finishing, so your projects will look great.

What Could Be Improved:

- The 5/8″ bore size might not fit all saws without an adapter.

- While durable, the orange chrome coating could potentially scratch with rough handling.

This blade is a solid choice for getting a professional finish on your woodworking projects. It’s a great investment for serious DIYers and woodworkers.

4. CMT 221.060.10 Industrial Cabinetshop Saw Blade

Rating: 8.6/10

The CMT 221.060.10 Industrial Cabinetshop Saw Blade is a powerful tool for serious woodworkers. This 10-inch blade boasts 60 teeth with a special TCG grind, making it ideal for tough jobs. It’s designed for heavy-duty crosscuts and leaves a super smooth finish, especially on panels with laminate on just one side. You can use this blade on radial arm saws, miter saws, table saws, and other special saws. It cuts through materials like chipboard, MDF, laminate, hardwood, and plywood with ease.

What We Like:

- It’s perfect for heavy-duty crosscuts and gives a clean finish on laminated panels.

- The micrograin carbide teeth stay sharp longer and make cuts smooth.

- The non-stick PTFE coating helps the blade run cooler, prevents sticky buildup, and protects against rust.

- It works great on a variety of materials, including laminate, hardwood, and plywood.

- The blade’s design ensures it lasts a long time and performs consistently.

What Could Be Improved:

- The kerf is 0.126 inches thick, which is slightly thicker than some very fine-cut blades, potentially creating a bit more waste.

- While great for laminates, for pure ripping or ultra-fine crosscuts on solid wood without laminate, other specialized blades might offer even finer results.

This CMT saw blade is a reliable choice that handles demanding tasks well. It’s built to last and deliver excellent results across many wood projects.

5. Freud Thin Kerf Ultimate Plywood & Melamine Saw Blade with Premium Tico Hi-Density Carbide Crosscutting Blend for Maximum Performance – 10″ Diameter

Rating: 9.3/10

The Freud LU79R010 is a 10-inch, 80-tooth saw blade designed for precision cutting. It excels at making smooth, chip-free cuts on materials like plywood, melamine, and laminates. This blade is a top choice for finish carpentry and cabinetmaking projects.

What We Like:

- It makes super smooth cuts with no chips on delicate materials.

- The special carbide blend makes it last longer and cut better.

- The sharp teeth are designed to prevent splintering.

- The special slots help keep the blade steady and quiet.

- The non-stick coating prevents sticky buildup and rust.

What Could Be Improved:

- The premium features might mean a higher price point.

- For very rough cuts, a different blade might be needed.

This Freud blade delivers exceptional results for projects requiring a clean, professional finish. It’s a valuable tool for anyone serious about woodworking.

The Ultimate Buying Guide: Plywood Blades for Your Table Saw

Cutting plywood can be a tricky business. You want smooth, clean edges, not a fuzzy mess. That’s where the right table saw blade comes in. This guide will help you pick the best plywood blade for your projects.

Key Features to Look For

When you’re shopping for a plywood blade, keep these important things in mind:

- Tooth Count: This is a big one. For plywood, you want more teeth. A blade with 60 to 80 teeth is usually ideal. More teeth mean smaller chips and cleaner cuts. Fewer teeth can tear the wood.

- Tooth Grind (ATB): Most plywood blades use an “Alternate Top Bevel” (ATB) grind. This means every other tooth is angled to the side. This helps the blade slice through the wood cleanly, reducing tear-out.

- Kerf: This is the width of the cut the blade makes. A “thin kerf” blade removes less wood. This means less dust and less strain on your table saw motor, especially good for smaller saws.

- Blade Diameter: Make sure the blade fits your table saw. The most common size is 10 inches. Always check your saw’s manual.

- Arbor Size: This is the hole in the center of the blade. It needs to match the arbor on your table saw. Again, 5/8 inch is standard for most table saws.

Important Materials

The materials used in a blade greatly affect its performance and lifespan.

- Carbide Tips: The teeth of good plywood blades are made of carbide. This is a very hard material. It stays sharp longer and can cut through tough materials. Look for blades with C2 or C3 carbide. C3 is harder and lasts even longer.

- Blade Plate: The main body of the blade is usually made of steel. High-quality steel is important. It keeps the blade flat and prevents it from warping when it gets hot.

Factors That Improve or Reduce Quality

Several things make a plywood blade great, while others can make it less effective.

- Good Quality Carbide: As mentioned, the carbide tips are key. Blades with thicker, higher-quality carbide tips will last longer and cut better.

- Precision Balancing: A well-balanced blade spins smoothly. This reduces vibration. Less vibration means cleaner cuts and a safer operation.

- Anti-Vibration Slots: Some blades have small slots cut into the blade plate. These slots help reduce vibration and noise. They are a sign of a more thoughtfully made blade.

- Cheap Materials: Blades made with low-quality steel or thin carbide tips will wear out quickly. They might also warp or become dull faster.

- Poor Tooth Count or Grind: Using a blade with too few teeth or the wrong tooth grind for plywood will lead to rough cuts and frustration.

User Experience and Use Cases

Using the right plywood blade makes a huge difference in your woodworking.

- Smooth Cuts: The best blades give you smooth, splinter-free edges. This means less sanding is needed. You can get beautiful finishes on your projects.

- Ease of Use: A good blade cuts through plywood easily. It doesn’t bog down your saw. This makes your work faster and more enjoyable.

- Versatility: While designed for plywood, many good plywood blades can also handle other sheet goods like MDF and melamine. Some can even cut hardwoods well.

- Types of Projects: These blades are perfect for cabinet making, furniture building, shelving, and any project where you cut sheet goods. Whether you’re a beginner or an experienced woodworker, the right blade will improve your results.

Frequently Asked Questions about Plywood Table Saw Blades

Q: What is the best tooth count for cutting plywood?

A: For plywood, you want a blade with a higher tooth count. Aim for blades with 60 to 80 teeth for the cleanest cuts.

Q: What does ATB mean on a plywood blade?

A: ATB stands for Alternate Top Bevel. It means every other tooth is angled sideways. This design helps slice through plywood and prevents splintering.

Q: Should I get a thin kerf or full kerf blade for plywood?

A: A thin kerf blade is often better for plywood. It removes less material, creates less dust, and is easier on your table saw motor.

Q: What are the teeth on good plywood blades made of?

A: The teeth are usually made of carbide. Carbide is a very hard material that stays sharp for a long time.

Q: How can I tell if a plywood blade is good quality?

A: Look for blades with high-quality carbide tips, precise balancing, and possibly anti-vibration slots. These features indicate a better-made blade.

Q: Will a plywood blade work on MDF or melamine?

A: Yes, most good plywood blades work well on MDF and melamine. They are designed for sheet goods.

Q: What is the most common blade diameter for table saws?

A: The most common diameter is 10 inches. Always check your table saw’s manual to be sure.

Q: Does the arbor size matter when buying a blade?

A: Yes, the arbor size is the hole in the center of the blade. It must match the arbor on your table saw, which is usually 5/8 inch.

Q: How important is blade balancing for plywood cuts?

A: Blade balancing is very important. A well-balanced blade spins smoothly, reducing vibration and leading to cleaner cuts.

Q: Can a plywood blade cut hardwood?

A: While designed for plywood, many high-quality plywood blades can also cut hardwoods effectively, though a blade specifically for hardwoods might perform even better.

In conclusion, every product has unique features and benefits. We hope this review helps you decide if it meets your needs. An informed choice ensures the best experience.

If you have any questions or feedback, please share them in the comments. Your input helps everyone. Thank you for reading.

Hi, I’m Hector Quintanilla, the creator of helmetslab.com.. As a passionate enthusiast and experienced expert in helmets, I’ve dedicated this platform to sharing my insights, knowledge, and hands-on experiences. Whether you’re seeking the best helmet for safety, comfort, or performance, my goal is to guide you with detailed reviews, tips, and advice. Ride safe, and let’s explore the world of helmets together!